Gate locks with code, panic exit or key? Different types of locks for gates

Not sure what gate locks with code or key are? Or what the difference between bolt-on locks and mortice locks is? It can be confusing as there are a few different types of gate locks depending on different categories.

Read on below as we cover:

Different types of gate locks based on installation:

Locks can be categorised in different types of installations. The material of your gate influences which of the below lock types you can use, as some of these won’t work for all gate materials. You can’t use a weld in lock on a wooden gate for example.

Note that the below categories aren’t necessarily mutually exclusive; i.e. you can have gate locks with code that bolt on or are surface fixed. So, one lock can be in a few of the below categories.

Bolt on locks

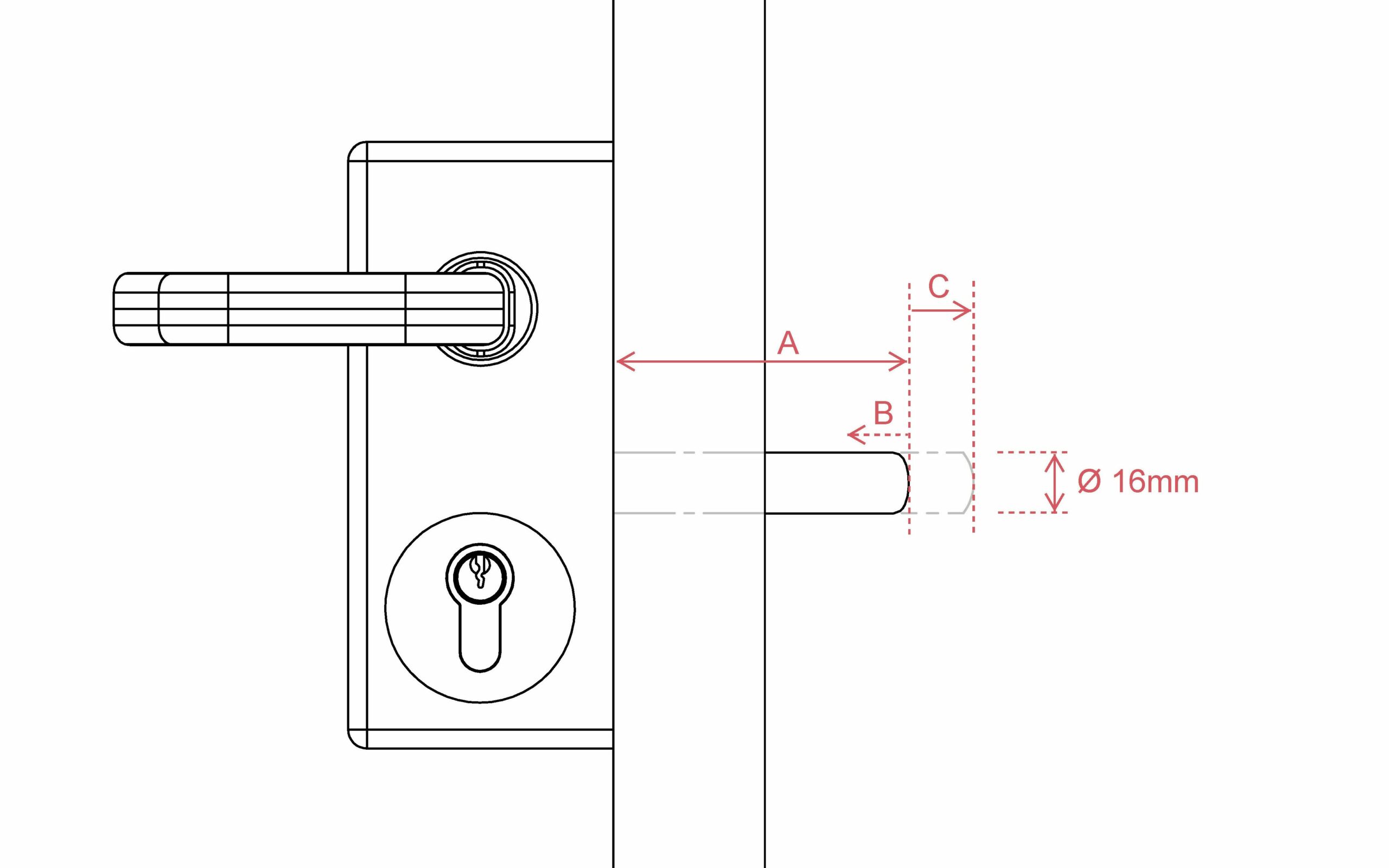

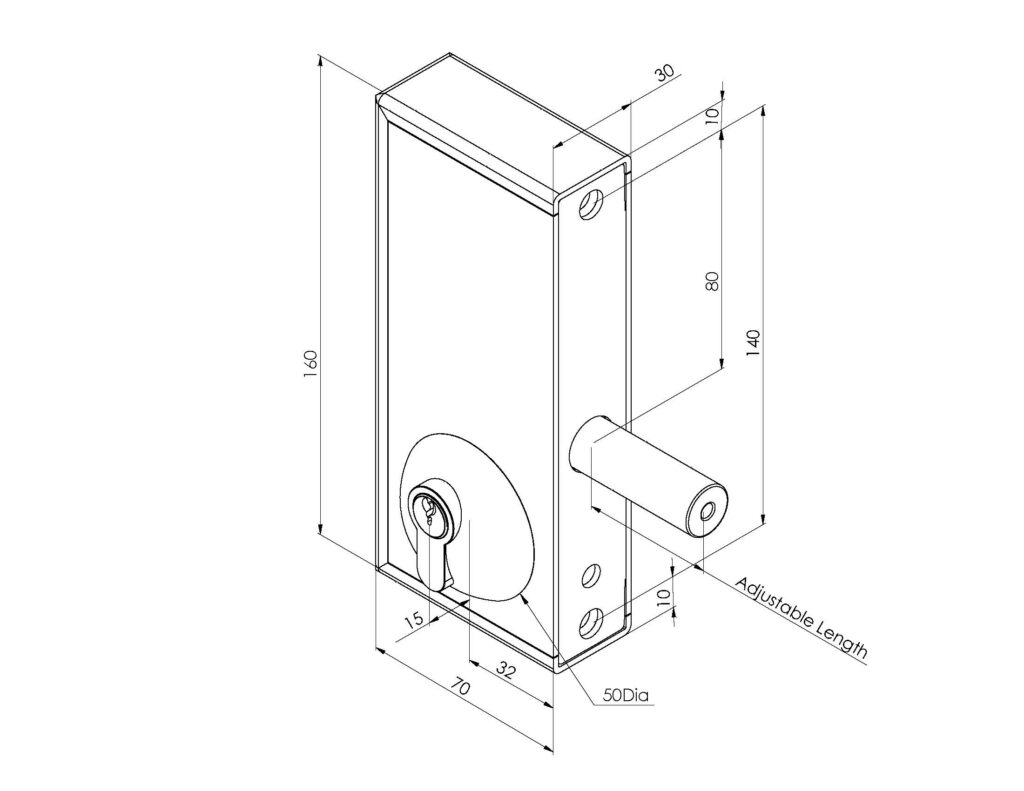

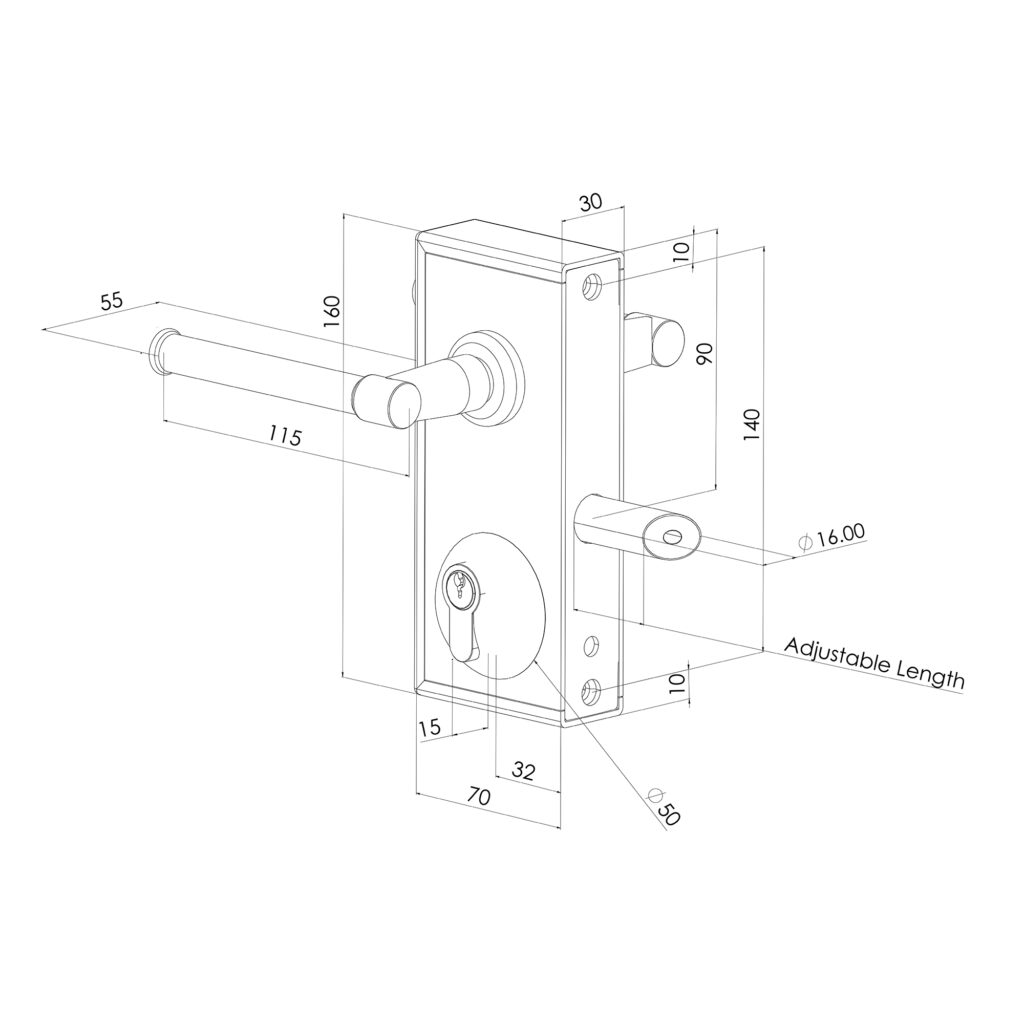

Bolt-on locks are locks that are fixed to the gate by being bolted on. They commonly require you to drill holes through the front profile of the gate through which they are installed with the supplied fixings. As shown below, they sit between the external frame of the gate and the internal bars.

Bolt-on locks are therefore mainly used on gates with a metal frame where a space can be created within the gate for the lock to be installed. If having a solid infill gate, you would need to cut a hole for the bolt-on lock to sit in which can make it more of a challenge to install the lock. The Gatemaster Superlock can be a great option for these scenarios with its slim case and removable locking bolt, meaning it can be fitted into very tight spaces. This range includes gate locks with code, key access and quick exits. See how easy it is to install in this video.

Bolt-on locks are useful for retrofitting to gates and can easily be replaced, if necessary, as most of them will use the same fixing holes.

Weldable locks

Where bolt-on locks sit on the back of the gate profile, a weld in lock will be integrated into it. To install a weld-in lock you cut out a section of the gate frame and weld in the lock case. The whole gate frame can then be sent off to be powder coated or painted, making the lock case virtually invisible. Once painted, the internal lock mechanism is installed within the lock case, and it’s done.

Inconspicuous, weld-in locks are both a secure and stylish lock option for metal gates. In terms of replacing a weld-in lock, it is often possible to buy the inner mechanism without the lock case. You can therefore easily switch them over and get a new lock in the existing welded lock case (if the casing is still up to scratch!).

Surface-fixed locks

Almost needless to say, but surface-fixed locks are locks that are installed by fixing them to the face of the gate. Surface fixed locks are an excellent solution for wooden gates as they can be installed with ease and don’t require any chiselling or morticing of the gate frame.

Most surface-fixed locks can also be fitted to metal or composite gate in addition to timber gates. The Gatemaster Locking Bolt for instance can be directly fixed to a wooden gate after cutting out a hole for the cylinder to reach the outside. The main lock is then installed with four timber screws. But it can also be fitted to a metal gate by using a weldable lock plate to fix the lock to as shown below.

For a simple, yet secure solution for your garden gate you can get surface-fixed gate locks with code, which can be installed quickly on your garden gate. We recommend using a keyless combination lock for wooden gates as it is a convenient solution and easy to use too. Read more about our Gatemaster options here.

Mortice locks

A mortice lock is a lock that is installed in a cut-out slot in the gate. They can be installed on both timber and metal gates, but they require a bit more gate preparation to install for both materials.

To install a mortice lock on a wooden gate, the installer would have to chisel out the slot to fit the lock inside which requires precision. This isn’t a problem for an expert carpenter or wooden gate specialist, and a mortice lock is useful as it sits flush on the front of the gate and is more inconspicuous than a surface-fixed lock for example.

For a metal gate, you would again have to cut out the correctly sized slot to fit the lock inside. To make it a bit easier for our customers, we actually offer a pre-cut box section for our ML4 mortice lock.

A mortice lock is a good solution for when you want an inconspicuous gate lock but don’t want to have to weld in a lock case. But time is money, so depending on the time you want to spend on installations and preparations, you might want to consider if a quick fit bolt-on lock is more suitable!

Different types of gate locks based on functions:

In addition to the installation process, locks are categorised based on the actual lock functions they have. Which one you choose depends on the needs and usage of the gate, so read on below to get the main features of deadlocks, latching locks and locks that can do both.

Deadlocking locks

A deadlock has a simple locking action operated by a key. When the key is turned, it will move the deadbolt and lock the gate. The gate is now locked and can only be opened again with the key.

Deadlocks won’t have any handles and can only be opened and closed with the use of a key.

You therefore have to remember to lock it behind you as it will not close otherwise.

Latching locks

A latch only lock cannot be deadlocked, and it will only latch. They will therefore always have a handle, or a thumb turn to operate the latch and open the gate or door.

Compared to the deadbolt, a latch bolt has a tapered/sloped end which helps close the gate lock. When opening the gate, you simply operate the handle, and the latch will retract. You can think of a latching lock in a similar way as a standard door latch, which can only open or close and not be locked.

Combined latching and deadlocking locks

Now we get to the good part! Some locks have a combined function and is able to both latch and deadlock.

These are commonly called latch deadlocks and will either have two bolts (one for latching and one for deadlocking) or a combined latch deadlock like our Superlock BLD, Select Pro weld-in SWLD to name a few.

As you can see in the video, a combined latch deadlock latches when closed but can be deadlocked with a key if necessary. If it remains unlocked, it is operated with the handles just like a normal door latch.

Different types of gate locks based on access:

The final grouping, we will cover today is based on the access (and sometimes exit) functions of the lock.

Gate locks with key

Key access locks are probably the most common type of access when it comes to gates. A simple key lock is beneficial to use in most cases and especially when the number of people using the gate is low or doesn’t change much.

They are also easy to source and can be found in most hardware shops.

Gate locks with code

Gate locks with code have many names: digital locks, keypad access, keyless lock, combination lock, code lock to name a few. Common for them all is the fact that they are opened by punching in a code on the keypad.

Gate locks with code are popular because they are convenient to use:

- No need for any keys

- No need to hand them out

- No need to have them replaced when losy or new people need access.

We offer keyless outdoor gate locks as either single-sided with keypad on the outside and lever handle on the inside, or double-sided with keypad on both sides.

Locks with keypad access can either be electronic or mechanical, both of which have their benefits (you can read more about that here).

Gate locks with push pads

A push pad lock has a button on the inside which releases the lock and allows you to open the gate. In our Superlock and Select Pro ranges, these buttons are large green pads built into the design to enable a quick exit.

A push pad lock is named this because of the way you exit the lock, and the outside access method can either be gate locks with code or a key access. You might therefore see a push pad exit lock under the other categories as well.

So, there you have it: some main categories of locks you will find and their main features.

Think we’ve forgotten to cover one? Let us know by getting in touch via email sales@gatemasterlocks.com.