The Gate Hardware Research and Development Journey

Gatemaster is founded on innovation and design and we take pride in continuing to develop new products (like our new Mortice Hook Lock). But how do we go from idea to a released product? Read about how we go through research and development for gate hardware below.

Research and Development for Gate Hardware

As anyone involved in research and development will know, it is rarely a straightforward process and sometimes it goes backwards, sometimes to the left and sometimes it is upside-down! But in the end, all our products go through the same overall steps.

The lightbulb moment:

As with everything, getting a brilliant new idea is the first hurdle. Luckily, we have been in the gate hardware industry for more than 25 years and as you can imagine, we have a lot of experience. Some ideas magically appear when reviewing our products and others are driven from customer demand and the market. Common for all is that we use our experience, knowledge, and design capabilities to come up with new products that are functional and solve a problem. As we are in control of the design, we are able to adapt to the needs of the market and our customers, while still ensuring functionality.

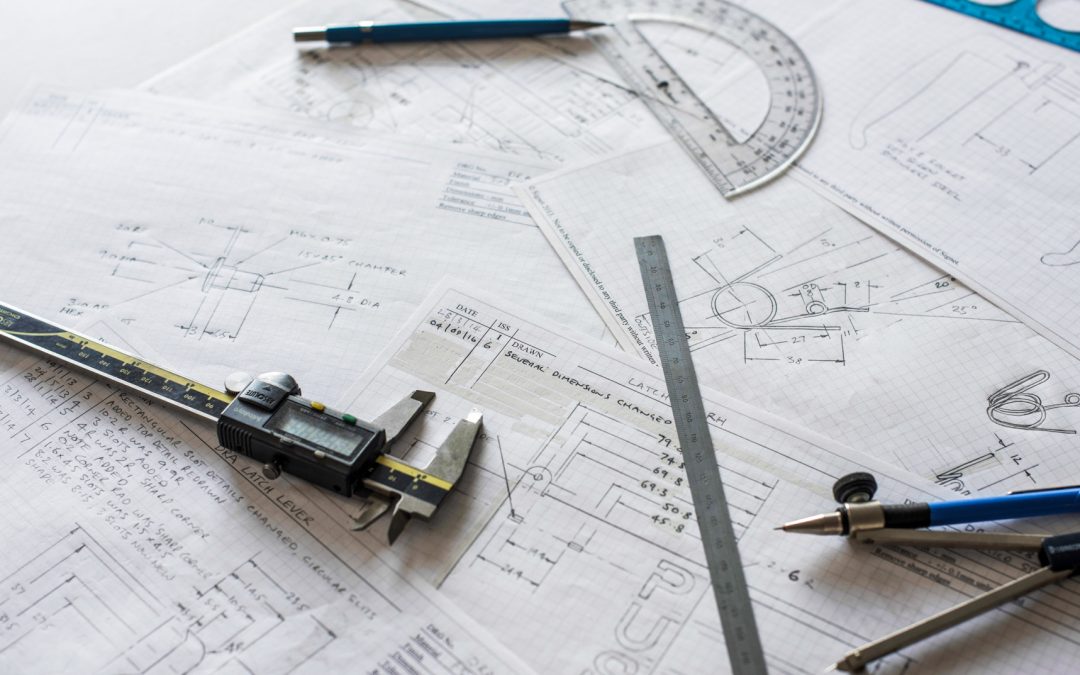

Drawing it up:

Once the idea has brewed and has been well-considered, we take it to the next step, which is drawing it. Doing the technical drawings takes time, but is imperative to lay out the proper design, get the right components and check how it could theoretically function. Sometimes, putting it on paper highlights issues, which need to be fixed before the next steps. Throughout the whole process, we keep going back to the drawings to adjust and tweak as we get more feedback and information.

Prototyping:

Once we’re happy with the initial drawings, we get to work and start making the first prototype. We take time to make up each component for the product, to check everything is correct right down to the millimetre. With gate hardware, reviewing each small component is important to make sure it all works as we intend. As you can imagine, this stage can take some time and more often than not, you need more than one prototype!

Putting it to the test:

As soon as we are happy with the prototype and its functionality, we get started on initial testing. These are designed to review the finished product in its entirety and to determine if anything is missing, if it works as smoothly as we want, and the overall performance. When doing research and development for gate hardware, this step is understandably very important.

Feedback is important to us and it is something we collect and gather throughout the whole R&D process. In fact, we make it a point to take our ideas to selected customers to see if they are interested and what they would need from a new product. Every time we make a larger change, we make sure to get feedback and take it in. For this reason, the research and development journey is very much like a game of ‘Snakes & Ladders’ as you are always moving up and down the board depending on the feedback and necessary changes.

The “final” product:

The prototype has now made it through testing and is now moving into production for the version to be sold. However, we don’t stop when our product is launched and on the market. In fact, the process of research and development for gate hardware continues after the product has been released as we are always reviewing our products. As a result, it is a continuous journey!

Real-life testing:

The product now goes through even more testing to see how durable, functional, and operational it is when used. We check all gate hardware products in terms of corrosion, wear, and general performance. For instance, we have automatic gate openers set up to test our locks to a certain number of openings.

Ready for launch:

Once final testing is complete and we’re happy with the results, the product is ready to be launched and sold to our customers. After the launch, we collect feedback as our customers install and use the products. This is a crucial step as we use it to find out if we should introduce related accessories that make the customer’s life even easier.

Goal (and onto the next project!):

Even after it launches, we continue to collect feedback from our customers and end-users to get an idea of how well it is working for them. Based on this, we might come up with a new idea or small adjustments to make sure it is continuously innovated. We want to provide suitable solutions that make life easier for our customers, while still upholding a high level of quality, durability, and standards. That means, the journey of our research and development for gate hardware never really stops!

Do you have any feedback or questions about our products?

Send an e-mail or give us a call +44 (0)1243 552066 and we will be more than happy to help!