The 5 best ways to slam proof your gate

Slam proof your gate to reduce the impact and noise of metal gates and give your customers a more peaceful life. Doing it from the beginning means you are less likely to be called back with complaints about a damaged gate, cracked paint, or just general annoyance with the noise. There are a few ways you can go about this, so read on as we give you the best ways to slam proof a gate.

Addressing the issue of slamming gates is also crucial for ensuring user safety. Slamming gates often lead to injuries if the gate suddenly closes as an individual passes through. Implementing a slam-proof APS closer, which provides controlled closing with adjustable dual-phase speeds, is the best way to meet safety standards.

The 5 most effective ways to stop gates slamming

Rubber buffer stops

If you are after a quick, simple way to slam proof your gate, you can install rubber gate buffers such as our Bump Stop (BS). It is simple to install with just a single fixing bolt and can be retrofitted easily. Rubber buffers reduce both the sound and the impact of a slamming gate.

With its simple installation, it is an obvious choice for a quick and efficient fix.

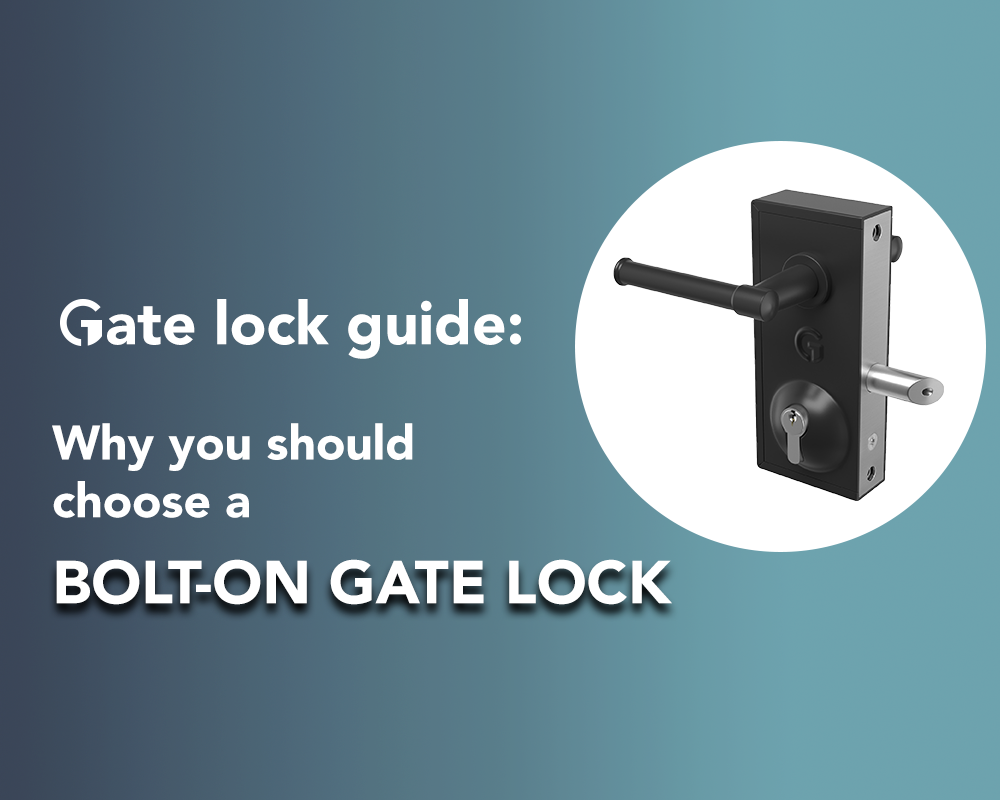

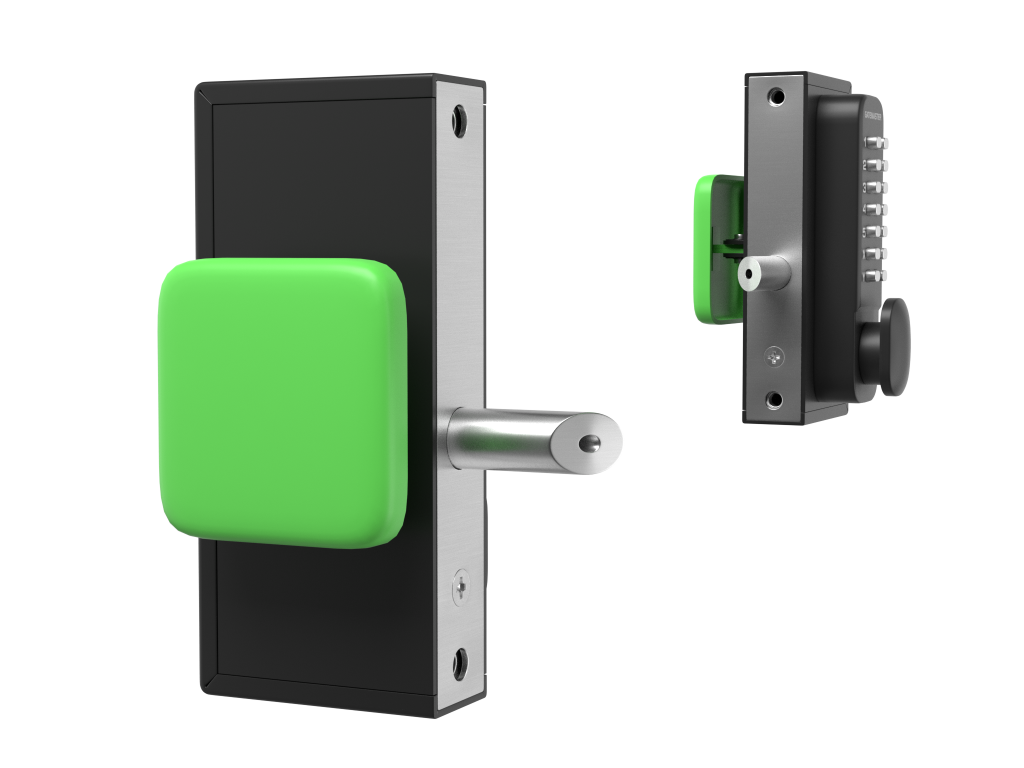

Gate slam plates

Another easy-to-fit solution is a bolt-on slam plate with integrated rubber buffers. They very much do what the rubber buffers do and reduce noise and vibrations from a slamming gate. Our GSK – Gate Silencer Kit is a great example of a noise reducing slam plate.

In addition to the rubber buffers, this slam plate also prevents the gate from being opened in the wrong direction.

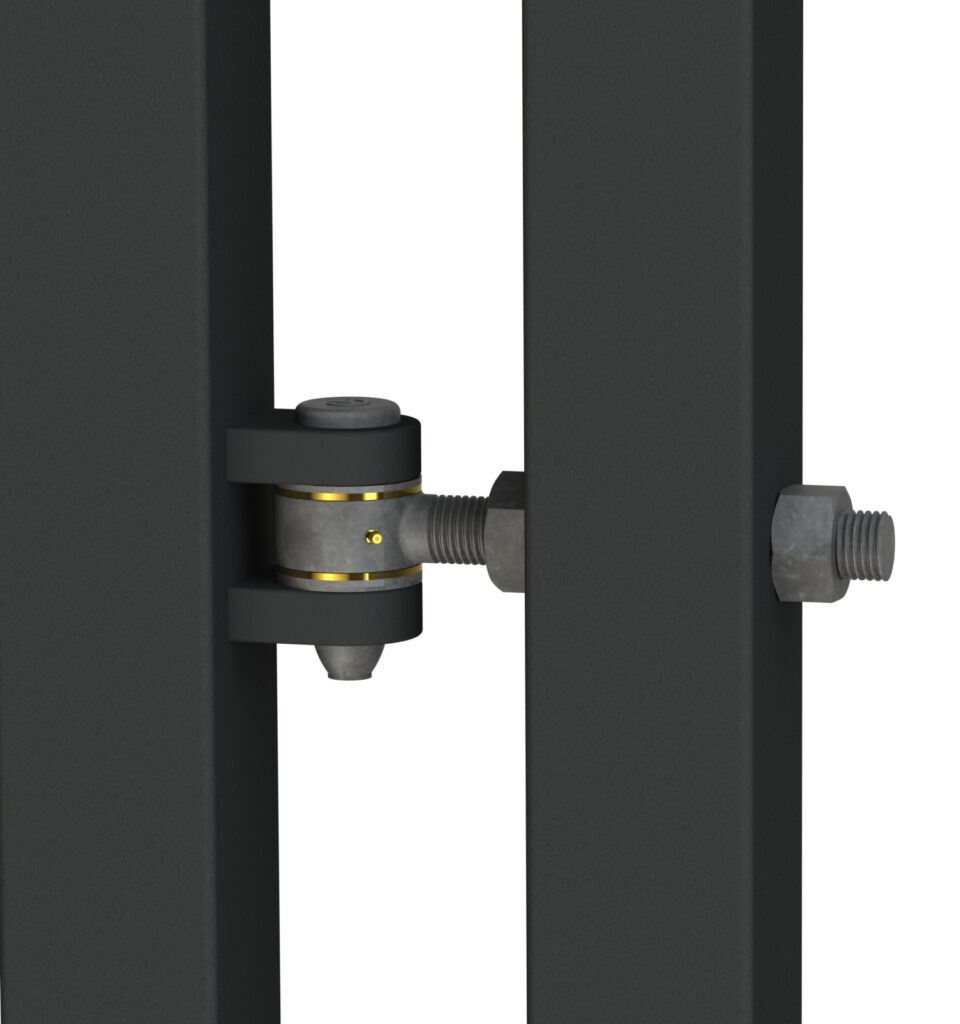

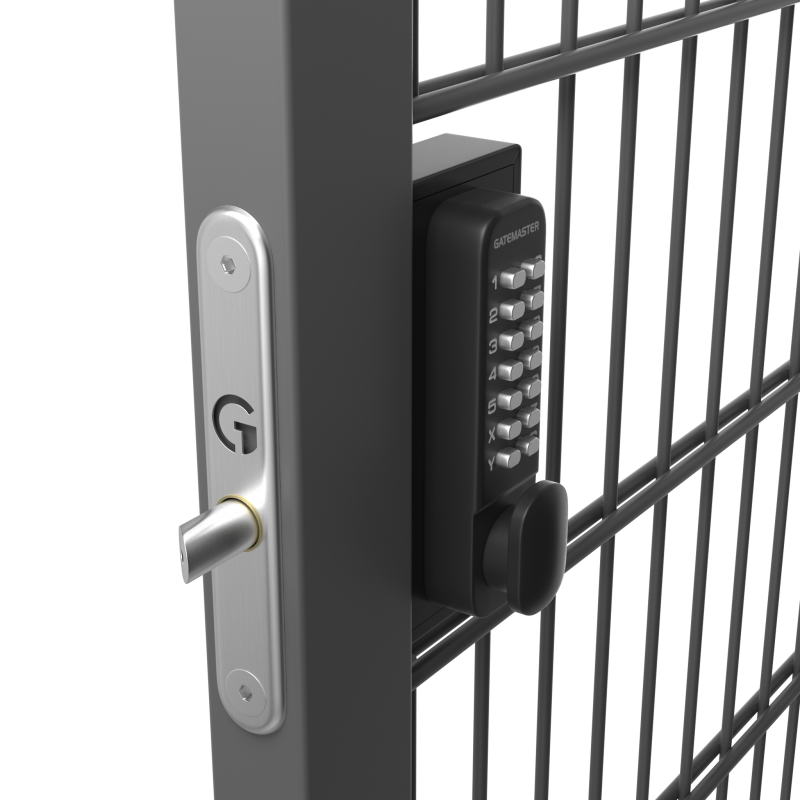

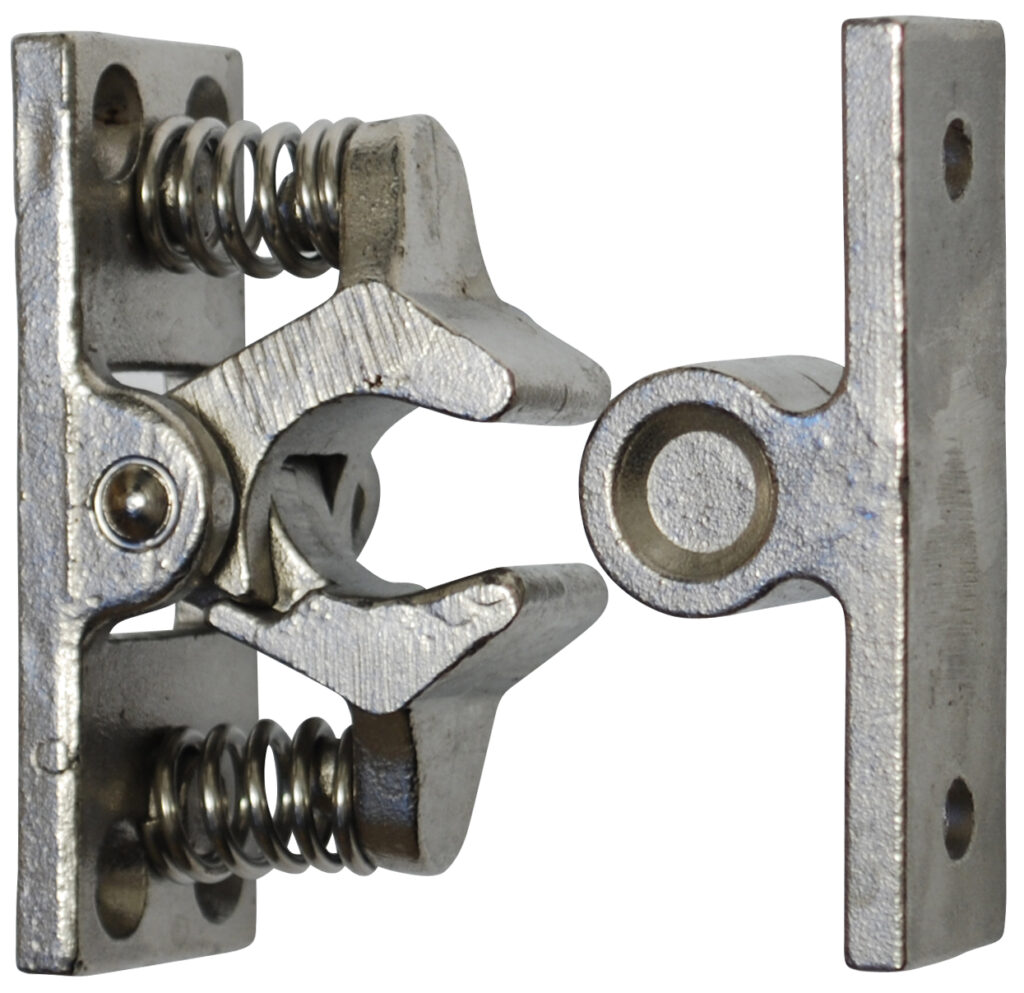

Keeps with integrated rubber buffers

A great way to slam proof your gate and potentially increase security, is to use a lock keep with integrated rubber buffers. Similar to the above solution, a keep with integrated rubber buffers will reduce the sound on impact.

But if you are already looking for a gate keep, check if it has a form of reducing the gate slamming. All our keeps have integrated buffers for this reason.

As a bonus, using a keep like our BSK or BSKS protects the latch bolt from four sides from prying hands and tools.

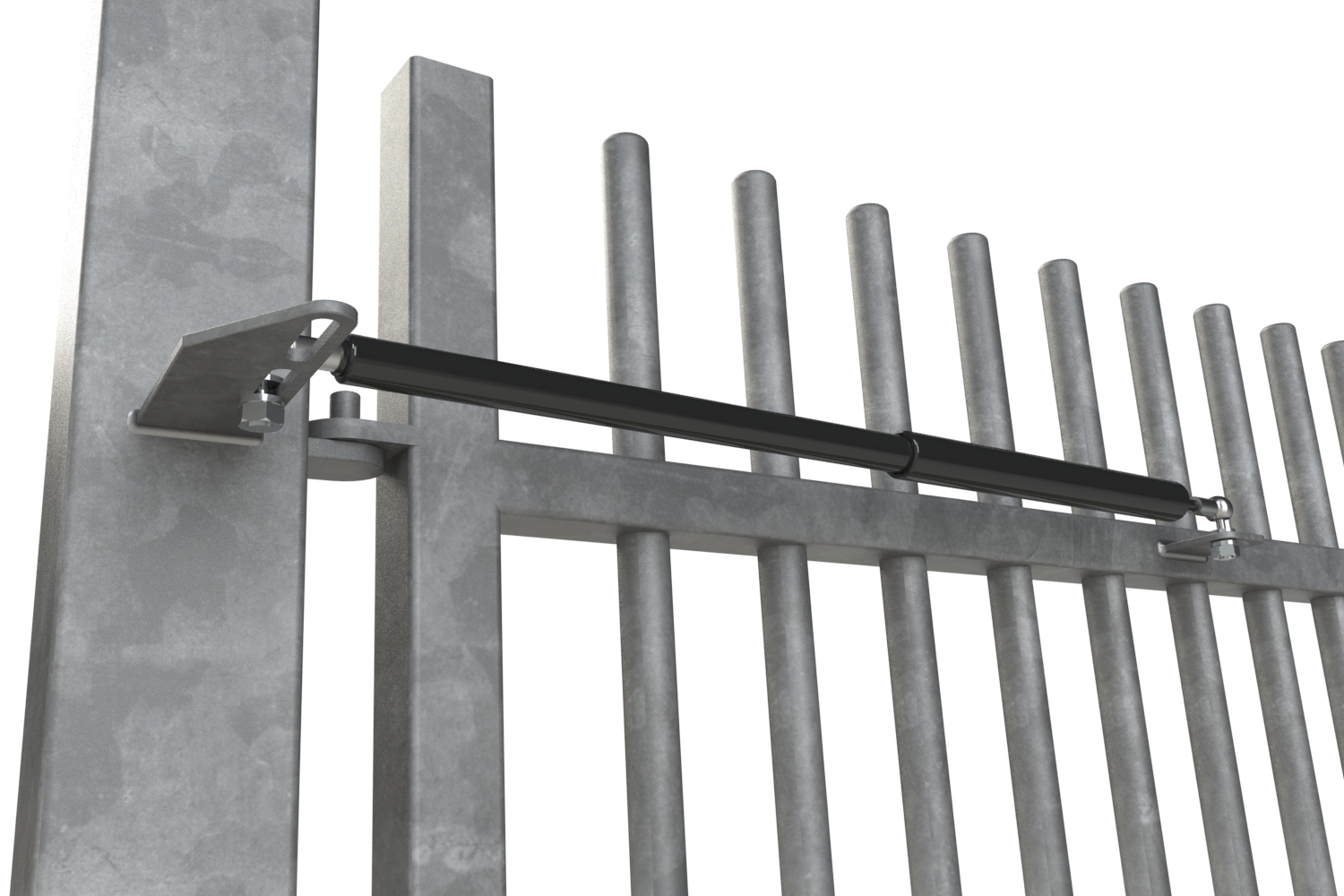

Controlled slam-proof gate closer and keep

The best way to slam proof your gate is to combine the use of a controlled gate closer and a rubber buffer of some sort. With this set-up you reduce the speed the gate closes at and therefore the impact, and you reduce the noise from the gate when it finally does close.

For an efficient slam proof gate, use the APS or GSB gate closers together with any of our keeps such as the BSKS interlocking keep. Not only will the slam-proof gate closer stop the gate from banging shut, but the integrated rubber buffers on the keep will eliminate the metal-on-metal sound of the gate closing. In addition to a quiet gate, the BSKS is also a secure keep solution as it further prevents outsiders from prying your gate open.

With controlled dual-phase closing speeds, the APS closer also makes gates safer by preventing the gate slamming shut, minimising risk of accidents and ensuring safety for users. With fully adjustable closing and latching speeds, the gate can be adapted depending on the use case.

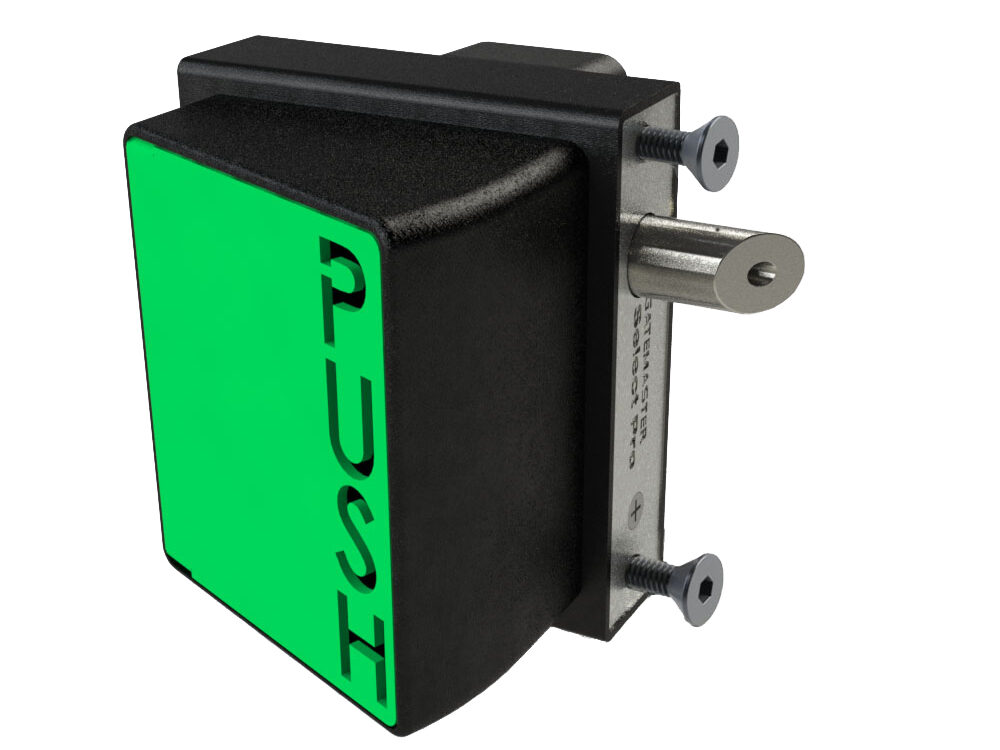

Gate stops and catches

The nuisance of gate slamming isn’t just when it closes though. Gates can easily be opened too quickly and slammed into an adjacent wall or post. This not only makes a racket but can also damage the gate over time due to the impact.

To stop this and slam proof your gate further, you can install a gate stop where the gate would normally hit. They are very similar to rubber buffers, as they also usually have a rubber end to reduce the noise and impact. They effectively stop the gate going too far thus eliminating the impact.

We’ve included gate catches in this grouping as they can be installed on the wall to keep the gate held open if required. It doesn’t really stop the gate slamming, but it is an extra feature you might find useful if already using a gate stop.

If any of the above ways to slam proof your gate sound of interest to you, contact our sales department and see how we can help you slam proof your customers’ gates.